The infrared thermography services provided by GEROPLEX INC. cover a vast

number of applications, from a brief survey up to a preventive program, depending on the request

of the customer.

Moulding under pressure, canalization losses, radiating panels, furnace degradation, engines

inspection, rubber injection, etc... are some of its specific fields of application. For such types

of applications, a study is done together with the customer in order to have a correct reading of

the situation and to precisely define his needs.

However, the most required application fields still are: insulation, roofing and electricity.

Some examples of these applications are described here.

|

|

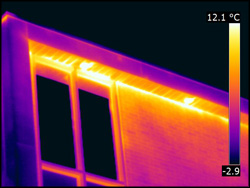

The thermographic image clearly shows an exfiltration of air at the top of the wall of this building.

|

|

|

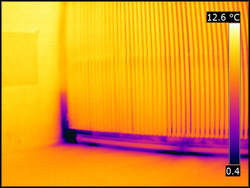

This thermographic image displays an important infiltration of air at the jonction wall/floor of this local.

|

|

|

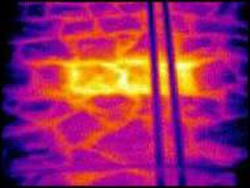

This thermographic image underlines well that this stone section is not insulated from the

inside.

|

|

The above images clearly show that the infrared thermography is the most suitable technique to

pinpoint defectiveness of a building shell, such as: air leakages, lack of insulation, thermal

bridges and dampness infiltration (it's a known fact that once dampness has infiltrated the insulator, it

may reduce the "R" factor down to zero). A thermographic survey is necessary prior to any

clever investment to reduce to a minimum the consumption of energy in a building.

|

|

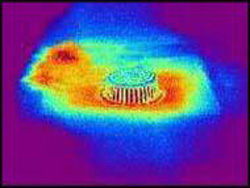

The thermographic image clearly shows a problem in the waterproofness of the membrane.

|

|

An inspection with our infrared-camera will allow us to detect the dampness existing in your roof insulation,

to locate precisely where water has seeped through the insulator and to assess the importance

of the repair works that could then be carried out quicker and cheaper. The weak areas will

undergo an additional survey by means of a hygrometer, and will be paint-marked directly on the

roof. All this is presented in a simple and complete report, showing the accurate position of the

weak areas thanks to real and infrared pictures.

|

As we can see on the pictures above, an abnormally warm point is a sign allowing to locate a

possible overheating problem, even maybe a latent fault. Thanks to an early detection of

defective components, the infrared thermography allows reduction of production stops and as such is

an ideal preventive maintenance tool. This advanced technology, recommended by all the

insurance-companies, is a very important asset to your company.

|

Statistics reveal that electricity is the first accidental

cause of fire in industries and it was generally caused by the overheating

of an electric component...

|

|

THE IMPORTANCE OF A PREVENTIVE MAINTENANCE

|

Infrared-cameras have been used in industrial maintenance for many years already. The infrared

thermography has been well tried. The financial profits generated by this maintenance technique

are very appreciable: one single survey lasting a few hours may avoid very expensive production

stops.

The aspect of security remains an other important advantage of having an infrared thermography

maintenance done.

But the most important asset of the infrared thermography is that it enables to assess the

serviceability of an equipment or an installation long before any actual fault and without having

to stop production.

|

It is however essential to rely on the services of a team expert in the field.

GEROPLEX INC. offers a qualified and accredited staff.

|

|